SERVO THERM S SPECIAL

Heat transfer phenomena is one of the most important and requisite step in industrial processing for indirect heating. Heat transfer media are materials used in industrial processes to transfer heat. In engineering and particularly in chemical and process engineering large quantity of heat has to be transferred at elevated operating temperature.

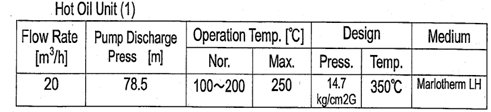

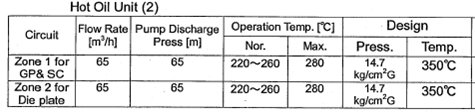

Thermal fluid heating is a type of indirect heating in which a liquid phase heat transfer medium is heated and circulated to one or more heat energy users within a closed loop system. In these cases, high boiling heat transfer media are recommended. HTF are thermally stable fluids used for indirect heating and cooling from -100 C to 400 C as circulatory media in hot oil systems. Different types of heat transfer fluids are used in industrial processes for transfer heat depending upon their operating temperature range.

Requirements of Heat transfer fluid (HTF)

A heat transfer fluid must possess the following characteristics :

- Low viscosity –Lower the kinematic viscosity of the heat transfer fluid faster the heattransfer.

- Excellent thermal stability In the operating range

- High flash / fire point

- Low pour point

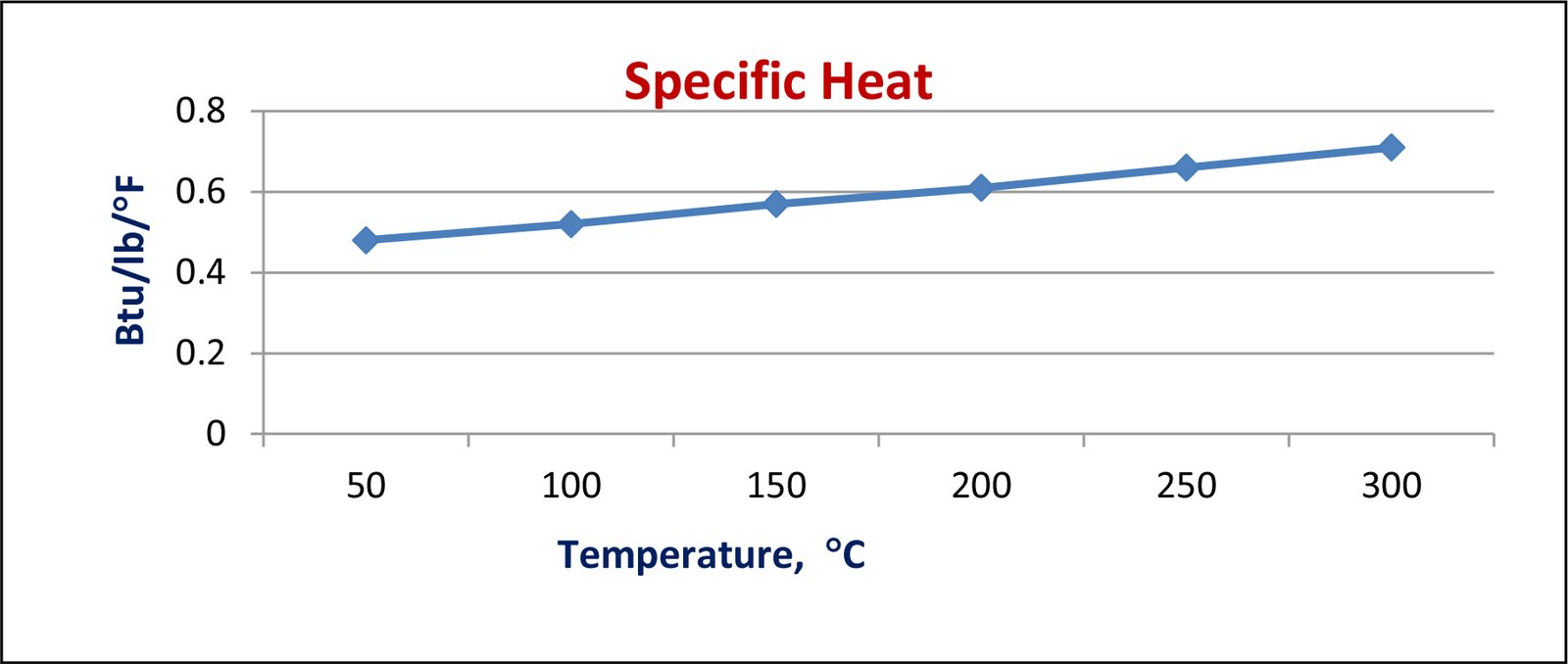

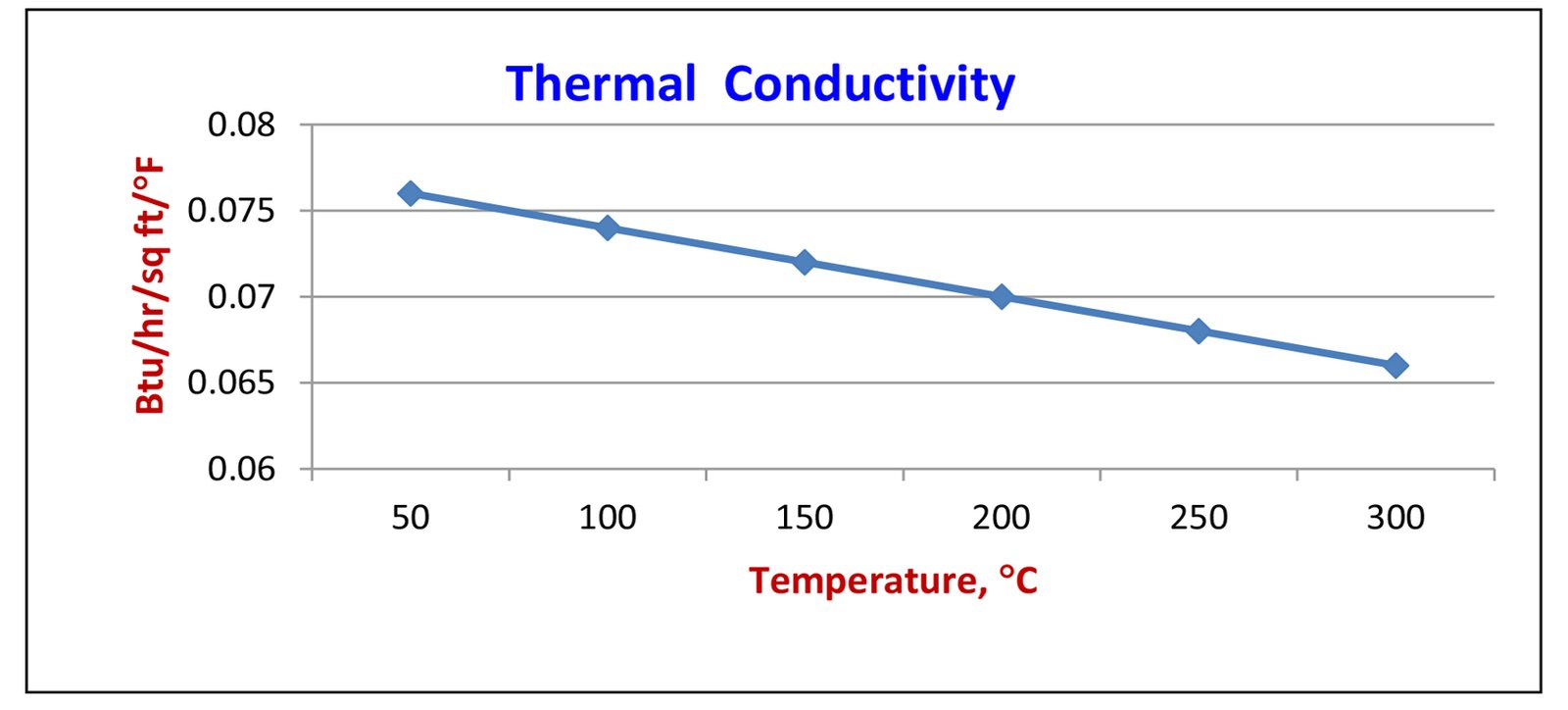

- High specific heat and thermal conductivity

- High resistance to oxidation

- High boiling point & low vapor pressure over the operating temperature range

- Broad fluid range applicability

- Low sludge formation and good solvency

- Non-toxic & odourless nature

Key Benefits :

Servotherm S Special offers the following advantages over conventional mineral fluids :

- Resist deterioration at the recommended temperatures to assure long fluid life and clean systems.

- Have low vapor pressures at operating temperatures to permit operation at atmospheric pressure.

- Possess good heat transfer characteristics.

- Low pour point and moderate viscosity with decreases the pumping losses and the power required for circulation.

- Excellent thermal and oxidation stability

- Low volatility

- Very low carbonaceous deposits and very good solvency